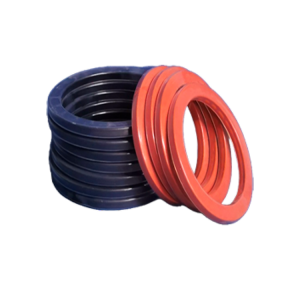

Manufactures standard and custom size O-rings that meet European and United States Pharmacopeia (USP) Class VI requirements. USP Class VI compliant compounds are formulated with ingredients that provide certifiable biocompatibility and low levels of extractables to achieve system purity and toxicity. USP Class VI materials are available in 70 durometer EPDM, silicone, and Viton™.

Ensures maximum biocompatibility and safety, meeting stringent USP Class VI standards.

Offers a selection of durable materials (EPDM, silicone, and Viton™) that maintain consistent quality across all applications.

Product Information:

When to use Silicone Encapsulated square section Gaskets?

In some applications such as processes in contact with food, chemical processes, pharmaceuticals, etc.; the use of conventional rubbers is prohibited. Corrosion or high temperatures can have devastating effects on O-rings, causing premature aging and failing to ensure the sealing seal, in these cases it is advisable to use silicone encapsulated square section gaskets.

Always used as a static gasket, FEP and PFA provide excellent chemical resistance, and the Silicone body a flexibility that plastic does not have. We will preferably use the silicone core (-60 to +260ºC) to work with products that require FDA regulations or that are in contact with food. The use of FEP jacket will limit stability to a lower temperature range than PFA, which will remain stable up to +260ºC, also having the property of superior resistance to abrasion and pressure.

When to use FKM encapsulated square section gaskets?

In those applications where high corrosion, as well as high and low temperatures are present or the use of conventional rubbers is prohibited, when in contact with acids, solvents, hydrocarbons, etc. These phenomena can have devastating effects on the sealing gaskets, causing premature deterioration and failing to ensure tightness, in these cases the use of FKM encapsulated square gasket is recommended.

Always used as a static gasket, FEP and PFA provide excellent chemical resistance and the fluoroelastomer body, a flexibility that plastic does not have. We will preferably use fluoroelastomer (-20 to +204 ºC), taking advantage of its chemical resistance. The use of FEP jacket will limit stability to a lower temperature range than PFA, which will remain stable up to +260 ºC, also having the property of superior resistance to abrasion and pressure.